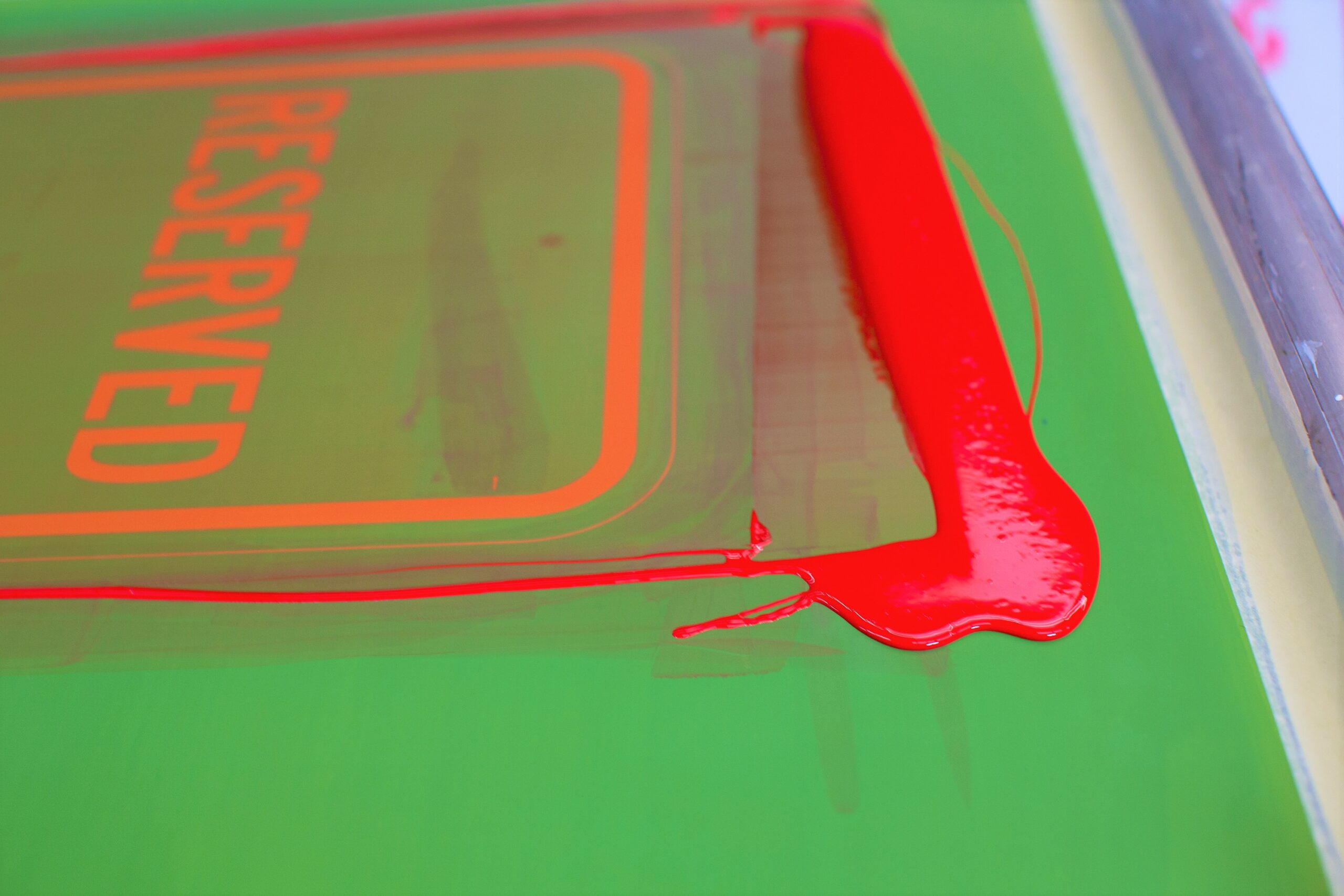

Ink and Ink treatments: Decorate to outlive your product lifespan

Print durability is often a primary concern when decorating a product for consumer or industrial use. It’s often critical that brand awareness is sustained and vibrant for the life of the product. Safety and convenience are also critical. Users must often be able to easily read printed instructions, symbols and other important information long into the future. Print durability, however, can be impacted positively or negatively in many ways during the manufacturing and print process. I will talk about ways you can ensure your product decorating techniques are designed to outlive your product life here.

For discussion purposes, let’s assume the product will be decorated by direct printing and then let’s consider your product material. The type of material your product is comprised of is an important part of the durability assessment for application of text and graphics. Most metals and their coatings are fairly well-known and have been consistent over the years so matching inks and processes for decorating with metals is relatively simple. Plastics, on the other hand, are a completely different story since there is a large variety of plastics available with more being added all the time. So, let’s explore today’s solutions for plastics.

Exploring durability and plastics

Things to avoid

Important considerations for plastics

For these reasons, I highly advise you to assess and test your print and ink treatments on sample parts, and that you test durability on your samples as early during your product development process as possible. Testing print treatments and durability under actual or simulated conditions earlier in your product development process allows you to observe print durability over time and provides you with the opportunity to address, or prevent, unanticipated decoration issues before production.

The ideal product decorator will have a variety of processes and inks to address all known and unknown adhesion and durability issues. Since plastics continue to evolve, however, there is no substitute for experience. And when durability of your product’s decoration is important test early and choose a decorator who has at least ten years of experience with printing on products like yours. As Albert Einstein said, “The only source of knowledge is experience”!